Stringless Machines at Work

Gomaco 280 Slip Form Paver with a Gomaco PS 2600 spreader attached finishing green concrete from 2 PS 2600 spreaders upstream. (note the prisms on poles at the left and right above the operator's head)

All 3 machines placing concrete. The 2 upstream spreaders used GPS for horizontal and vertical positioning. The slip form paver on the other hand needs the more precise double robotic total station set up to control the mid line of the machine and place the pre-finished concrete within 0.02' of design vertical.

A 3rd robotic total station is not seen, but is used in a 'leap frog' set up. As the slip form paver moves out of range of the downstream robot, the 3rd robot has been set up upstream and is on line and ready so the paver does not need to idle excessively.

The lack of stringlines allows for more efficient operations to take place such as the middle PS 2600 spreader with a side chute that allows concrete to be loaded while operating. The loading conveyor can be seen in the photo of the 3 machines above.

The finished product - 17" thick.

Gomaco GT 3600 with the curb mold mobilizing to the beginning of the run. Note the Robotic Total Station prism on the pole to the left of the operator which precisely controls the mold and the GPS antenna towards the front of the machine for guidance.

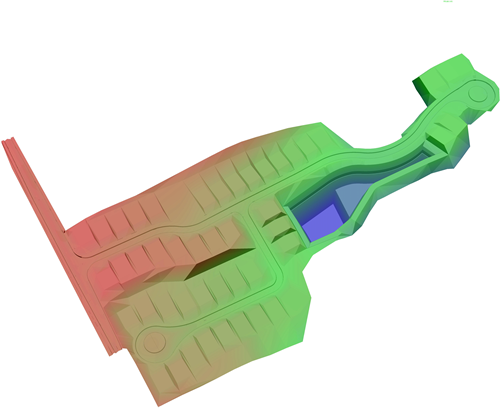

3D modeling for stringless operations can solve lots of job site issues like fire hydrants where the strings would have gone.

The finished product. Note the Leica TCRP 1201+ Robotic Total Station to the right.